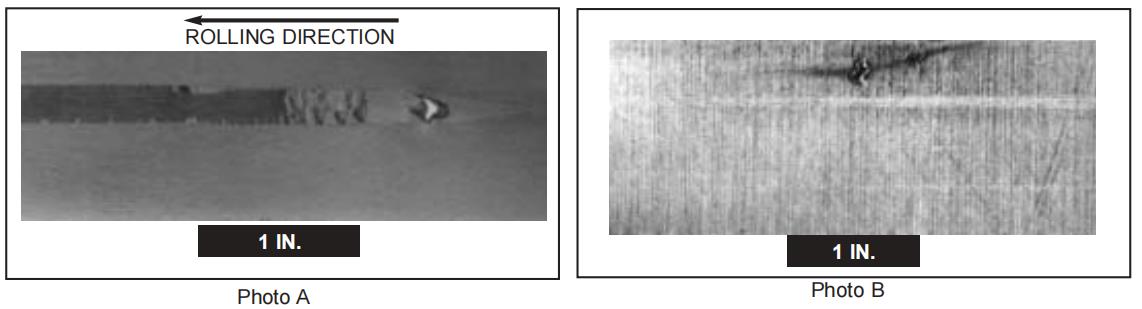

INCLUSION, STRINGER—

In the process of metal pressing and heating, the metal scraps fall on the strip and are formed after rolling; during hot rolling, the number of roll edges is few, and the cracked metal falls on the strip; the quality of the disc shearing edge is not good, and the edge of the strip is There are burrs, and the compressed air does not blow off the metal chips on the surface of the belt plate; after the roller sticks to the aluminum, press the sticky aluminum block on the belt plate; the guide ruler is too tight, and the scraped scraps fall on the plate.

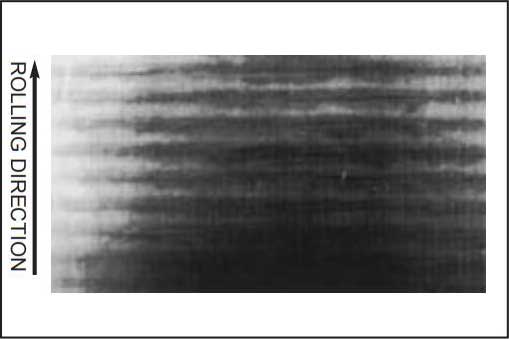

WAVE—

The wave roll shape is not adjusted correctly, the original roll shape is not suitable; the shape control system is faulty or improperly used; the original shape of the cold rolled wool is poor or the convexity in the section is too large; the selection of process parameters such as reduction ratio, tension and speed Improper; various types of straighteners are not well adjusted, and the gap between the straightening rollers is inconsistent, causing waves on the thin side of the sheet; for stretch-straightening and stretch-bending straighteners, the elongation rate is not selected properly.

ROLLED-IN METAL—

The roller table of the hot rolling mill is scratched, and the guide plate sticks to aluminum, so that the hot-pressed plate is scratched; the guide plate and pinch roller of the cold rolling mill have protruding sharp corners or stick to aluminum; they are scratched by the guide during the processing of the finishing machine; the finished product When packing, the lifter is not properly lifted.